HMI

Product Details:

- Input 1.2 A

- Power Supply 500 watt

- Product Type HMI

- Application Industrial

- Rated Voltage 240 Volt (V)

- Supply Voltage 500 Watt (w)

- Warranty Yes

- Click to view more

HMI Price And Quantity

- 1 Unit

- 4500.00 - 15000.00 INR/Unit

HMI Product Specifications

- Yes

- 500 watt

- Industrial

- 1.2 A

- HMI

- 240 Volt (V)

- 500 Watt (w)

HMI Trade Information

- 100 Unit Per Day

- 1 Days

- All India

Product Description

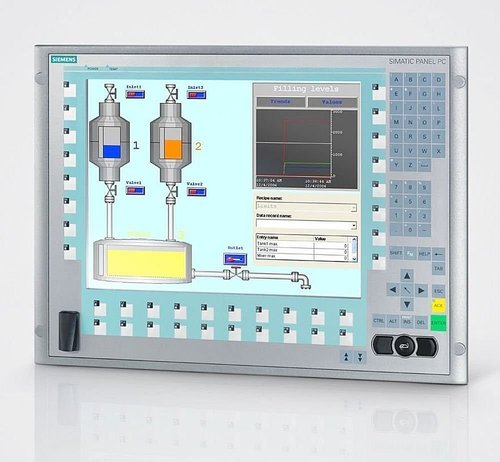

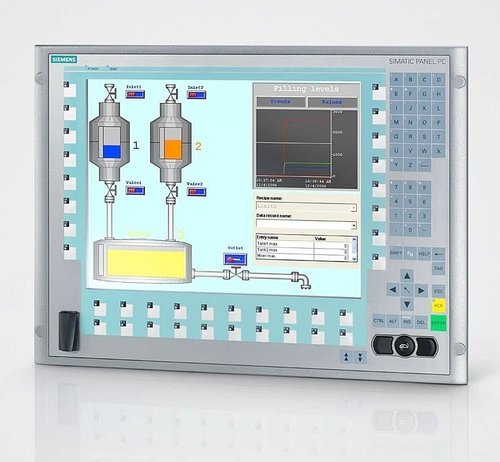

HMI stands for Human Machine Interface which is used in different industries like agribusiness, automotive, tablets, PC, mobile phone. With 800x480 pixel resolution and 64K colors, offered product is known for high efficiency, less maintenance and optimum quality. It works as platform between users and automation equipment. It allows user to touch image on user-friendly window. HMI is equipped with 2 Ethernet ports with switch function and 2 USB Host ports.

This is a simple to use interface that makes a productive connection between machines and humans. It boasts of high usability as well as optimal effectiveness. With the utilization of HMI, a user can make make less effort without compromising on the improved productivity. Apart from presenting the information and controlling the different active functions, it ensures an optimum monitoring over various automated systems. Adding HMI to your workplace can make amendments in productivity, safety and operation. It allows for an optimum control, effortless management and impeccable visualization of the operations made by devices' processes.

Human Machine Interface Applications

HMI can be used in multiple industries, such as:

- Pharmaceuticals

- Manufacturing plants

- Food and beverage

- Vending machines

- Utilities

In many of these industries, an HMI is the production line's backbone, improving operations significantly. An HMI enables data acquisition, supervisory control, enhanced stock control and control of every aspect of manufacturing lines.

HMIs make technologies easier to use. An HMI is judged on its usability, and its effectiveness impacts the entire system. An HMI should perform the function a user needs for a given task, allowing the user to expend less effort while improving productivity.

An HMI should do more than present information and control functions it should also provide users with active functions, information on system performance and feedback on results.

Human Machine Interface Applications

HMI can be used in multiple industries, such as:

- Pharmaceuticals

- Manufacturing plants

- Food and beverage

- Vending machines

- Utilities

In many of these industries, an HMI is the production line's backbone, improving operations significantly. An HMI enables data acquisition, supervisory control, enhanced stock control and control of every aspect of manufacturing lines.

Accurate Testing With SimulationPlant managers can test equipment and devices easily through the use of an HMI with simulation. Testing can be achieved in the office without any piece of equipment. This function improves overall production and reduces startup time.

Cost ReductionA human machine interface can reduce operating costs by replacing hundreds of selectors, push buttons, indicator lights and more. This means the need for extra cables, panels and consoles is also greatly reduced.

Improved CommunicationHMI can also improve communications throughout the facility by using various types of equipment. This includes the use of:

- Ethernet

- Data Highway Plus

- DDE (Dynamic Data Exchange)

- Remote I/O

Other Products in 'HMI (Human Machine Interface)' category

|

EMBICON TECH HUB

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |