Busbar Conductor System

120 INR/Box

Product Details:

- Shape Rectangular

- Overheating Protection Yes, with insulation and optional thermal sensors

- Feature Anti-corrosive, Shock Resistant, Low Maintenance

- Mounting Type Suspended / Surface Mounted

- Surface Finish Powder Coated / Anodized

- Connector Type Bolted/Clamp Type Joint Connectors

- IP Rating IP55 / IP65

- Click to view more

X

Busbar Conductor System Price And Quantity

- 120 INR/Box

- 1 Kit

Busbar Conductor System Product Specifications

- High; >98% transmission efficiency

- Dependent on busbar length and rating, typically 28 kg/m

- Up to 95% non-condensing

- PVC/Polycarbonate/High Grade Plastic

- Applicable as per load type

- -30C to +80C

- Bolted/Clamp Type Joint Connectors

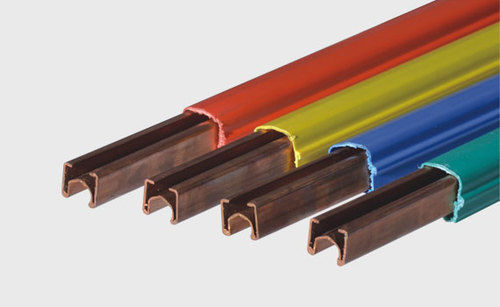

- Orange, Red, Green, or as per order

- IP55 / IP65

- Joint with expansion connectors, bolted/coupler joints

- Electrical Conductor Rail

- 3 or 4

- 40A to 2000A current ratings available

- Three Phase / Single Phase

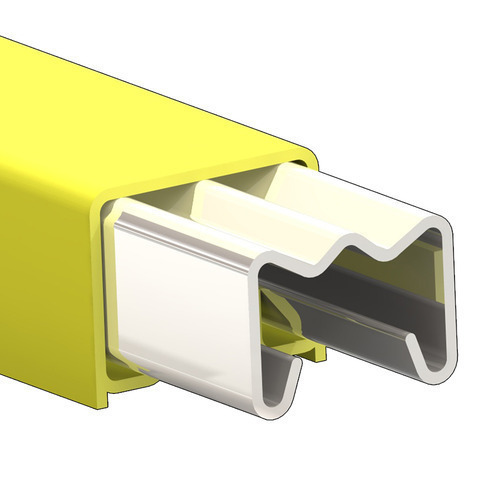

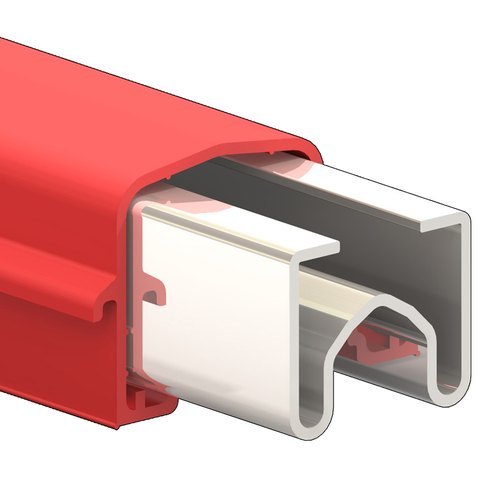

- Enclosed Insulated Busbar Conductor System

- 415V AC or as required

- 50/60 Hz

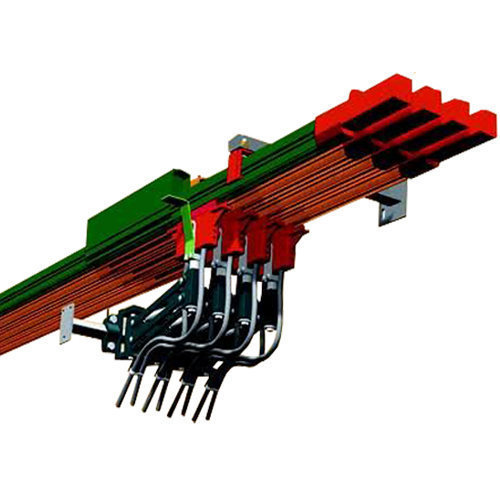

- Power Distribution in Industrial and Commercial Settings, Overhead Crane Power Supply

- Up to 690V AC

- Anti-corrosive, Shock Resistant, Low Maintenance

- Powder Coated / Anodized

- Suspended / Surface Mounted

- Copper/Aluminum with Insulated Housing

- Depends on connected load

- High Protection, Insulated Housing

- Rectangular

- Yes, with insulation and optional thermal sensors

- Typically 4m/6m length sections, custom width and height

Product Description

Busbar Conductor System

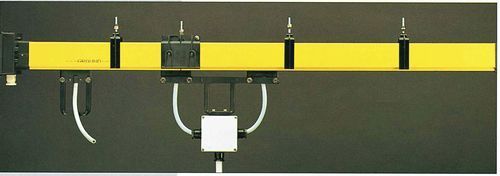

Busbar Conductor System is defined as a conductor or a cluster of conductors that used for collecting electric power from the incoming feeders and then supplied them to the outgoing feeders. In other words, this device is an electrical junction in which incoming and outgoing electrical current meets. Our company is specialized in manufacturing this Busbar Conductor System and has served a lot of customers with the same. If you are also looking for this system get in touch with us.

- Rail Length [mm]: 4.000

- Outside-Dimensions of bar profile: 2.20" x 3.54" (56.0 mm x 90,0 mm)

- Support Spacing: 6.56 ft (2 meters)

- Operating Conditions: For indoor and outdoor applications

- Track Configuration: Straight course; curve segments available by request

- Current Range : 40 Amps, 60 Amps, 80 Amps, 100 Amps, 120 Amps, 140 amps, 160 Amps, 180 Amps, 200 Amps

- Maximum Running Speed: 278.9 feet/minute (85 meters/minute)

Electrical properties:

- Max. Voltage(V): 600

- Rail Length [mm]: 4.000

- Conductor cross section(mm2): 10 - 16 - 25 - 35 - 50

- Resistance( /km): 1.656 - 1.137- 0.713 - 0.522 - 0.337

- Leakage resistance: CTI600-2, 7

- Dielectric strength: 30-40KV/mm

- Track Configuration: Straight course / Curve segments on request ( R 1.2m )

Mechanical properties:

- Flexible strength: 75N/mm2 10%

- Tensile strength: 40N/mm2 10%

Temperature range:

- Common Housing: -30C up to +60C

- Housing: -20Cup to +115C

Superior Safety and Protection

Engineered with high-grade insulation and self-extinguishing materials, the busbar system provides high protection (IP55/IP65) against electrical hazards and environmental stress. Overheating protection is achieved with optional thermal sensors and robust construction, making it ideal for sensitive industrial use.

Flexible and Efficient Power Distribution

The modular nature of the Busbar Conductor System, with adjustable current ratings from 40A to 2000A and customizable section dimensions, allows tailored solutions for varying load requirements. Its adaptable to single or three-phase applications and can handle load fluctuations, maintaining efficiency above 98%.

Low Maintenance and Durable Design

Featuring anti-corrosive, powder-coated, or anodized surfaces, the busbar system is built for longevity in demanding ambient conditions (30C to +80C, up to 95% humidity non-condensing). Accessories such as current collector trolleys and hanger clamps streamline installation and minimize long-term maintenance efforts.

FAQs of Busbar Conductor System:

Q: How is the Busbar Conductor System installed in industrial settings?

A: Installation is straightforward due to modular sections (typically 4m or 6m lengths) and supported accessories, such as current collector trolleys, end-feed kits, and hanger clamps. The system can be suspended or surface mounted and connected using bolted or clamp-type joint connectors.Q: What are the main benefits of using this busbar system for power distribution?

A: Key benefits include improved electrical safety, high protection levels (IP55/IP65), rapid installation, low maintenance, and remarkable flexibility in handling different current ratings and applications. Its anti-corrosive and shock-resistant properties ensure reliable, long-term performance.Q: Where can the busbar conductor be used, and what environments is it suitable for?

A: This system is suitable for a wide variety of applications such as industrial power distribution, overhead crane supply, and commercial use. Its robust insulated housing and high dielectric strength make it ideal for both indoor and outdoor installationseven in challenging ambient conditions.Q: When should I consider using copper vs. aluminum conductors in my application?

A: Copper conductors are recommended when superior conductivity and minimal voltage drop are important, while aluminum offers a lighter, cost-effective alternative for less demanding loads. The choice often depends on current rating, budget, and installation environment.Q: What process is involved in customizing the busbar system to specific requirements?

A: Customization is achieved by selecting appropriate current ratings (40A2000A), conductor material (copper or aluminum), number of poles (3 or 4), insulation level, lengths, and mounting style. Accessories and connectors further adapt the system to unique project needs.Q: How does the busbar system ensure operational safety?

A: Operational safety is handled through insulated, self-extinguishing housing, high dielectric strength (>20 kV/mm), rigorous short-circuit withstand capacity (up to 80 kA), and optional thermal sensors for overheating protection, minimizing risk to personnel and equipment.Q: What is the typical maintenance required for this busbar system?

A: Routine maintenance is minimal owing to its durable, anti-corrosive construction and robust insulation. Occasional inspections for wear on accessories (like current collector trolleys) and checking connection tightness help maintain peak efficiency and safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bus Bar System' category

|

EMBICON TECH HUB

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |