Cable Carrier

Product Details:

- Feature Flexible, Durable, Lightweight, Easy Installation

- Condition New

- Material Engineering Plastic / Polyamide (Nylon)

- Application Cable Management in Automation & Industrial Machineries

- Loading Capacity Suitable for Cables and Hoses, varies by model

- Click to view more

Cable Carrier Price And Quantity

- 100 INR/Piece

- 1 , , Piece

Cable Carrier Product Specifications

- Suitable for Cables and Hoses, varies by model

- New

- Flexible, Durable, Lightweight, Easy Installation

- Engineering Plastic / Polyamide (Nylon)

- Cable Management in Automation & Industrial Machineries

Cable Carrier Trade Information

- 1 , , Piece Per Day

- 1 Days

Product Description

Cable Carrier

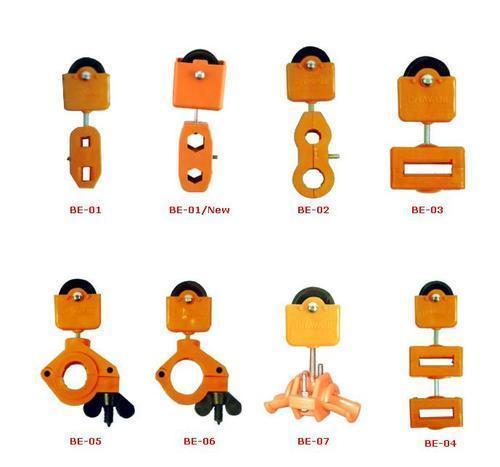

Cable Carrier is also called drag chains or energy chains that have hoses connected for moving automated machinery. This products reduce wear and stress on hoses and cables, prevent entanglement and enhances operator safety as well. These can be arranged to accommodate rotary, vertical, horizontal and three-dimensional movements. We are manufacturing and supplying this Cable Carrier along with the assurance of quality. Our company is constantly working in the direction to make clients happy as it is the key to survive in the competitive market.

Product details

| Capacity | 0.5-2 Ton |

| Material | Metal |

| Size | ALL |

| Application | Fastoon system, Crane spare, EOT Crane, Material handling |

| Packaging Size | ALL |

Optimized for Industrial Demands

This cable carrier is engineered specifically for use in industrial automation, robotics, and machine tool applications. Its robust design ensures reliable cable protection, even in rigorous and repetitive motion scenarios, improving operational safety and efficiency for diverse machinery.

Superior Material & Resistance

Constructed from premium-grade polyamide (nylon) engineering plastic, the drag chain is highly resistant to oils, corrosion, and wear. This enhances its lifespan and makes it suitable for challenging environments without the need for additional surface treatment.

Easy Installation and Flexibility

The end bracket mounting system allows for swift, hassle-free installation. Its lightweight, flexible construction adapts to various cable and hose layouts, streamlining maintenance and reducing downtimes in your automated systems.

FAQs of Cable Carrier:

Q: How do I select the appropriate cable carrier model for my application?

A: Selection should be based on your cable or hose dimensions, required bending radius, and the load capacity needed. Measure the inside height and width required, as well as the movement radius, then choose a model matching these specifications.Q: What is the process for installing the drag chain onto industrial machinery?

A: The cable carrier features an end bracket mounting type, enabling quick attachment to machinery frames. Simply align the end brackets with the designated mounting points, secure them using suitable fasteners, and route your cables or hoses through the chain.Q: When should I consider replacing a cable carrier/drag chain?

A: Inspect for visible signs of excessive wear, deformation, or reduced flexibility, especially in high-cycle or harsh-operation environments. Replacement is recommended if the carrier becomes brittle, cracked, or if it no longer provides adequate protection to the cables or hoses.Q: What benefits does the UL94-V2 flame-retardant rating provide?

A: UL94-V2 flame retardancy means the drag chain has been tested for fire safety and will self-extinguish within a certain period if ignited, reducing fire hazards in industrial environments. This rating varies by the specific material of each model.Q: Where is this cable carrier commonly used?

A: It is widely installed in automation lines, robotics, CNC machine tools, and material handling equipment across industries, especially where cable management, protection, and reliable motion are crucial for system integrity.Q: How does the drag chain ensure low noise operation?

A: The engineering plastic and precise design minimize friction and vibration during movement, which significantly lowers operational noise, making it suitable for environments sensitive to sound levels.Q: What is the main advantage of using a self-colored, polished finish on the cable carrier?

A: A self-colored, polished finish enhances durability, resists staining from industrial environments, and eliminates the need for additional surface treatments, simplifying maintenance and ensuring a consistent appearance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Crane Control System' category

|

EMBICON TECH HUB

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |