Bolt Jointed Bus Bar

Product Details:

- Mounting Type Panel Mounting

- Overheating Protection YES

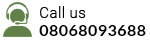

- Insulation Material PVC / Heat Shrink Sleeve

- Shape Flat

- Connector Type Bolt Connection

- Surface Finish Tin Plated / Bare Copper

- Operating Temperature -10C to 110C

- Click to view more

Bolt Jointed Bus Bar Price And Quantity

- 360 INR/Box

- 1 Kit

Bolt Jointed Bus Bar Product Specifications

- 3

- Three Phase

- Custom Sizes Available

- Copper

- Up to 95% RH

- Conductive Bar

- 415 V

- IP54

- High Conductivity, Durable

- -10C to 110C

- Copper

- Tin Plated / Bare Copper

- 415 V

- Custom as per requirement

- Bolt Connection

- PVC / Heat Shrink Sleeve

- Flat

- High

- Bolt Jointed Bus Bar

- YES

- 50-60 Hz

- Bolt Jointed

- Power Distribution

- Panel Mounting

Product Description

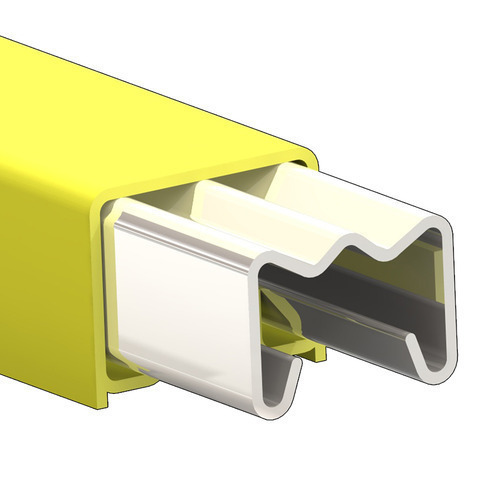

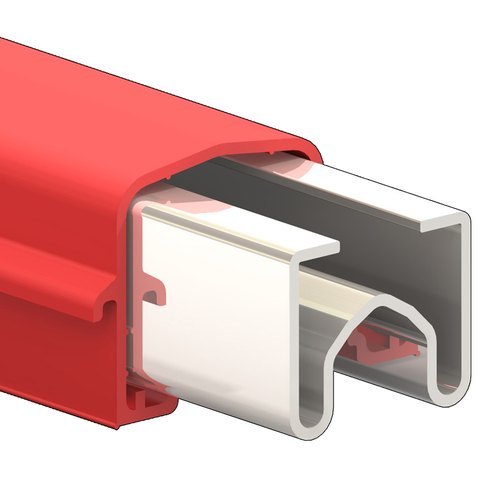

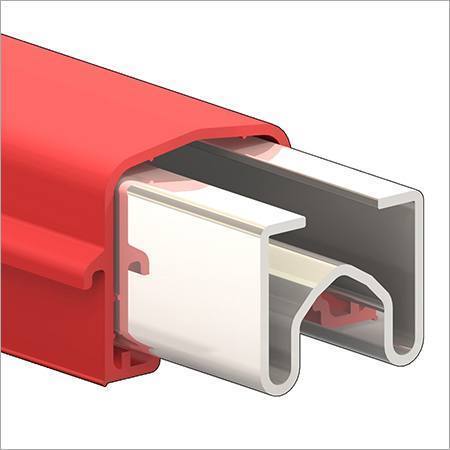

Bolt Jointed Bus Bar

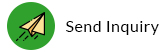

We are offering Bolt Jointed Bus Bar that is made by overlapping the bars and bolting via an overlap area. The item is reliable, compact and versatile, which we deliver along with the assurance of quality. All the customers are impressed with the performance and durability of this item and they have rated our company as an excellent entity. We feel overwhelmed to see our customers satisfied and we are continuously putting efforts to make them delighted with our Bolt Jointed Bus Bar.

Product details

| Available Material | G.I and Copper |

| Features | SAFE |

| Color | ALL |

| Brand | EMBICON |

| Material | GI,AL,COPPER |

| Product Code | DSLBUSBAR |

| Coating | PLASTIC |

| Current | 0-1600A |

| Frequency | 50 Hz |

| Voltage | 440 |

| Product Type | BOLT JOINTED BUSBAR |

| GI Current Capacity | 80 Amp to 125 Amp |

| Copper Current Capacity | 135 Amp to 315 Amp |

Robust Quality and Customization

This copper Bolt Jointed Bus Bar stands out with its high mechanical strength, corrosion and fire resistance, and enduring conductivity. Custom dimensions ensure compatibility with varied panel mounting requirements while deburred edges enhance safety during handling and installation. Choose between tin-plated or bare copper finishes for the best fit.

Engineered for Safety and Compliance

Tested rigorously for protection, this bus bar provides high-level safety features such as IP54 ingress protection, overheating safeguards, and RoHS compliance. The PVC or heat shrink insulation ensures electrical insulation up to operating temperatures of 110C, and supports high humidity environments up to 95% RH.

Ideal for Power Distribution Applications

Designed specifically for robust power distribution, the bolt jointed connection ensures secure and reliable performance. Applicable across industries, including commercial and industrial electrical panels, it guarantees efficient, loss-minimized transfer of electrical current in three-phase setups, fulfilling both standard and custom requirements.

FAQs of Bolt Jointed Bus Bar:

Q: How is the Bolt Jointed Bus Bar installed for power distribution panels?

A: The bus bar is designed for panel mounting and utilizes bolt jointed connections for secure installation. Custom sizes ensure a proper fit, and deburred edges simplify handling. The mounting process typically involves securing the bar within the panel using bolts, ensuring tight and reliable electrical contact.Q: What customization options are available for this bus bar?

A: Customization includes dimensions (length, width, height), thickness (3mm to 12mm), and surface finish (tin plated or bare copper). Additional options include client-specific insulation materials, connection types, and design features to suit unique installation or usage requirements.Q: When should a high conductivity bus bar like this be used?

A: This bus bar is best utilized when high current transfer (up to 630A), low energy loss, and robust protection are requiredsuch as in main power distribution panels in commercial and industrial facilities. Its durability and safety features make it suitable for demanding environments.Q: Where can these bus bars be sourced or used in India?

A: These bus bars are made available throughout India by multiple distributors, dealers, exporters, manufacturers, retailers, traders, and wholesalers. They are commonly used in applications demanding reliable and safe power distribution, including electrical substations, control panels, and industrial plants.Q: What benefits does the fire and corrosion resistance provide?

A: The fire and corrosion resistance extend the operational lifespan of the bus bar, ensure electrical integrity even under harsh conditions, and simplify maintenance. This resilience is crucial for industries requiring stable and safe power delivery over long periods.Q: How does the bus bar support safety and regulatory compliance?

A: With an IP54 rating, RoHS compliance, PVC or heat shrink insulation, and built-in overheating protection, the bus bar adheres to stringent safety and environmental standards. These features collectively safeguard equipment, personnel, and sensitive environments from electrical hazards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Bus Bar System' category

|

EMBICON TECH HUB

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |